Software Integration

ATS World Wide will partner with the airport to determine the optimal taxiway layout of the ATS system then customize and upload the ATS software suite for ground traffic controllers to operate the entire system. The software integration is planned late in the installation project schedule in order to minimize disruptions to airport operations.

System Training

ATS World Wide offers an array of training options for airport personnel, to include a customized simulated system, onsite ATS expertise and classroom training.

Installation Cost Estimate

Implementation of ATS system by airports will require an initial investment costs and operating costs for system maintenance.

| Installation Estimates |

USD |

Euro |

| 1 m (1.1 yd) ATS system cost |

$3,121 |

€2,800 |

| 1 ATS pull car cost |

$78,026 |

€70,000 |

| Project cost (% of total system cost) |

5% |

5% |

| Annual Mx cost (% of total system) |

4% |

4% |

One option to recuperate an airport’s investment in ATS is to charge usage fees to airlines. Estimated fees are less than the cost of fuel burned during traditional ground taxing creating economic benefits to both the airlines and airport system. For this option, airline ATS usage fees are estimated to cost approximately 60% of saved fuel during taxi.

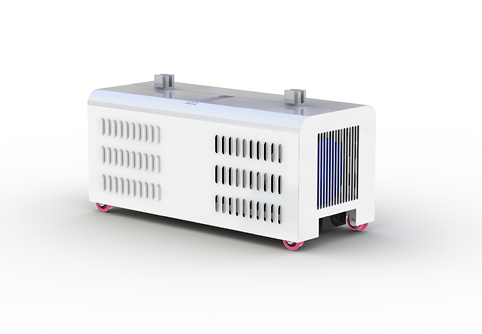

ATS Operations and Maintenance

The ATS system is fully automatic and operated by airport personnel through the airport traffic control system software using lasers on the pull cars to help transport aircraft. Approximately 10 employees are required to operate the entire ATS system at a large airport. An additional 10 employees are estimated to maintain the ATS system for an average size airport. These personnel maintain the system in air traffic control tower, monitor software and hardware functionality, maintain the channel and pull cars, and detach aircraft from pull cars if necessary to transport aircraft by traditional means. The ATS channel and pull cars will require periodic inspections and maintenance. Prior to installation, ATS World Wide will determine recommended spare parts, tooling and support equipment required to operate and maintain the system.

Detaching from ATS System During Transport

At any time during ATS operations, the pilot or ground controller can detach the aircraft from ATS system in approximately 45 seconds or less. The pilot has the ability to disengage the ATS system at his or her discretion. After the aircraft detaches from the pull car it can move under its own power or be towed by traditional means. This event has no impact to other aircraft operating under the ATS system. All other aircraft in the system receive an alert regarding the detaching event and the system will continue to operate.

Required Aircraft Modification

In order to disconnect from a pull car, an aircraft may require minor modification to its software; however, detachment can also occur via ground controllers. No other aircraft modifications are anticipated.

Environmental Protection

Significant reduction in aircraft fuel consumption, due to not operating engines during taxi under ATS, dramatically reduces harmful emissions emitted into the atmosphere. They are as follows:

Carbon Monoxide

Carbon Dioxide

Hydrocarbon

Nitric Oxide

Reduction of harmful emissions help improve the environment. The global use of the ATS system can play a very important role in improving the environment. Airports can apply for government grants for environmental protection by implementing ecological systems such as ATS. The emission reductions may be monetized by converting the savings into emission credits and selling them to companies paying fines for emission violations.

The table below shows savings in emissions of different harmful substances:

| Harmful Substance Consumption |

Emission from aircraft (oz/gal) |

Emission from aircraft (g/L) |

| Hydrocarbon |

0.06 |

1.71 |

| Carcinogenic Nitric Oxide |

0.16 |

4.60 |

| Carbon Monoxide |

0.73 |

20.62 |

| Carbon Dioxide |

0.13 |

3.70 |

Operating Parameters

ATS system has a very high rate of return on investment (ROI) after installing the system. Main parameters influencing the ROI are as follows:

Fuel consumption

Number of flight movements

Taxiing time

Length of taxiways

Number of ground crew required to operate the traditional system

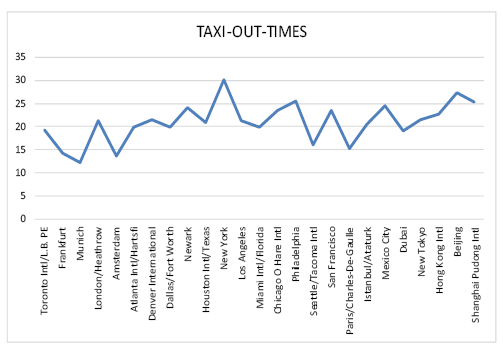

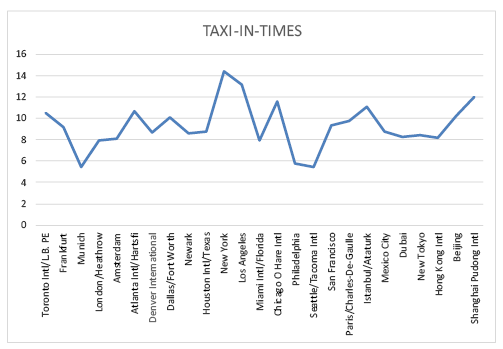

These parameters very for each airport and have significant impact on the ROI. On page 16 is an analysis of three key operating parameters (KOP) – fuel price, number of flight movements and length of taxiing time.

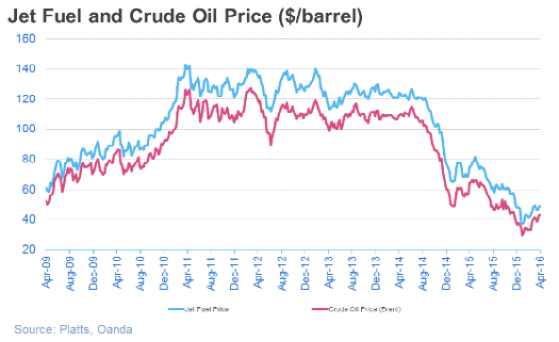

Fuel Prices

One of the major advantages of implementing ATS system for aircraft transport at an airport is significant fuel savings. Aircraft engines (on medium and large airfields) burn an average 35 liters (9 gallons) of fuel/minute. For example, taxi time at Frankfort Airport averages 16 minutes per flight, which translates to burning approximately 560 L (148 gal) of fuel on every aircraft movement. Utilizing the ATS system allows the aircraft to power down engines shortly after landing and conversely, aircraft are not required to use their aircraft engines until reaching the runway for take-off and only perform the required engine run-up just prior to takeoff. Depending on the type and size of aircraft, fuel usage for 1 minute of taxiing is 20-70 liters (5-18 gal) per minute. Average fuel usage for passenger aircraft is 35 liters (9 gal) per minute while taxiing. Prices of fuel have a significant impact on the amount of savings from fuel usage; see graph below.

Crude oil analysts agree the price of oil is predicted to rise in the near future. It may not reach the record levels of $140/barrel, but even at $80-90/barrel, oil prices affect airline costs. With each price increase of crude oil, the ROI for utilizing ATS increases.